Minichannel-based Solar Collectors

Solar thermal systems provide the capability of generating heat, electric power, and/or cooling in a sustainable way and for a variety of applications due to the relatively large range of temperatures that different collector configurations provide. Currently, a key issue that remains a subject of intense research relates to effectively transferring the energy obtained from the sun to the working fluid. Increasing the efficiency of solar water heaters has the potential to have a high impact on the consumption of natural gas and other fuels in the residential and commercial sector.

Solar thermal systems provide the capability of generating heat, electric power, and/or cooling in a sustainable way and for a variety of applications due to the relatively large range of temperatures that different collector configurations provide. Currently, a key issue that remains a subject of intense research relates to effectively transferring the energy obtained from the sun to the working fluid. Increasing the efficiency of solar water heaters has the potential to have a high impact on the consumption of natural gas and other fuels in the residential and commercial sector.

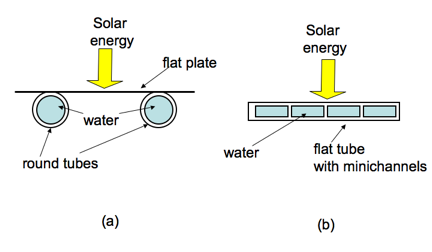

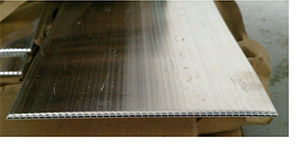

Minichannel heat exchangers, sometimes called microchannel, have been successfully utilized in the automotive, air conditioning, and electronics cooling industry due to their improved performance and compact size compared to round-tube plate-fin heat exchangers. However, the transition to minichannel technology has not taken place yet in the solar thermal industry. Minichannel tubes are usually produced by extrusion. They have a rectangular cross sectional area with ports inside.

Minichannel heat exchangers, sometimes called microchannel, have been successfully utilized in the automotive, air conditioning, and electronics cooling industry due to their improved performance and compact size compared to round-tube plate-fin heat exchangers. However, the transition to minichannel technology has not taken place yet in the solar thermal industry. Minichannel tubes are usually produced by extrusion. They have a rectangular cross sectional area with ports inside.  This provides an additional advantage for solar water heaters. In the minichannel collector design the fluid is directly in contact with the tube wall that receives solar radiation, thus, reducing the thermal resistance. The temperature along the tube wall is also more uniform as opposed to the temperature profile of the flat plate collector.

This provides an additional advantage for solar water heaters. In the minichannel collector design the fluid is directly in contact with the tube wall that receives solar radiation, thus, reducing the thermal resistance. The temperature along the tube wall is also more uniform as opposed to the temperature profile of the flat plate collector.

R&D is currently being performed to manufacture and test an aluminum solar water heater that uses minichannel tubes as absorber. This project is funded by the California Energy Commission, contract # POEF01-M04.

Additional funding is being sought to manufacture a medium temperature minichannel based collector. For further information, please contact Prof. Gerardo Diaz.